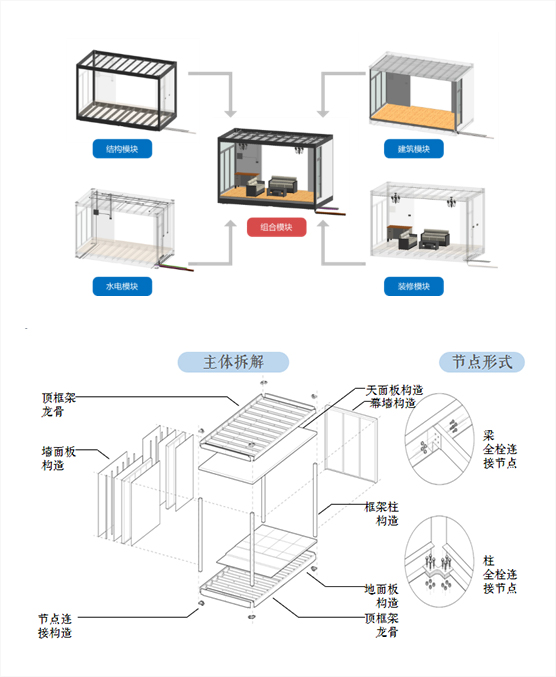

Modular construction represents an advanced form of prefabrication, where buildings are broken down into three-dimensional modules. Each module is fully outfitted with interior finishes, plumbing, and MEP (mechanical, electrical, and plumbing) systems in the factory. On-site, these modules are assembled much like ‘Lego blocks,’ allowing for the swift completion of the entire project. Currently, China Construction Science and Industry Green Technology Company specializes in two primary structural systems: steel MiC (Modular Integrated Construction) and concrete MiC.

High efficiency

Saving materials and labor,high efficiency.

60

%

High Quality

Improvement in the assembly rate

90

%

Greening

Reduction in solid waste and carbon emission

92

%

Intensification

Saving materials and labor.

60

%

Product series

Module building

Module construction is a progressive type of prefabricated building. Using a proprietary system, buildings are produced in modular units, encompassing everything from structures to finishes, plus utilities like water and electricity. These modules are designed for seamless on-site assembly, with a high rate of over 95% completion, making them move-in ready. This approach is suitable for a variety of building needs.

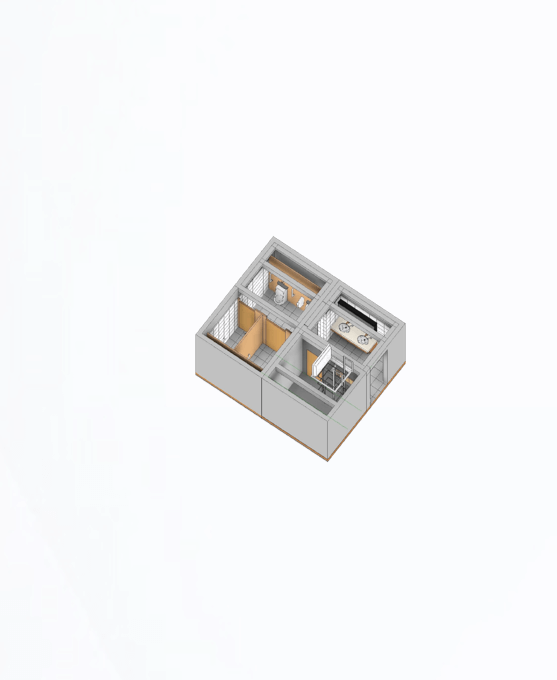

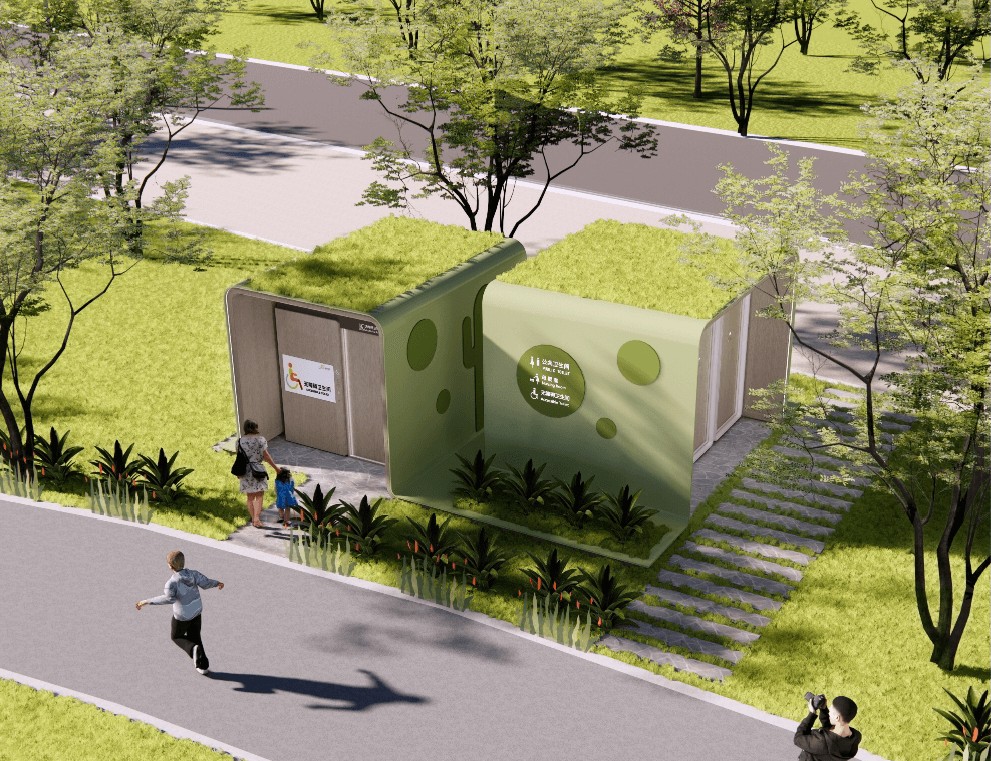

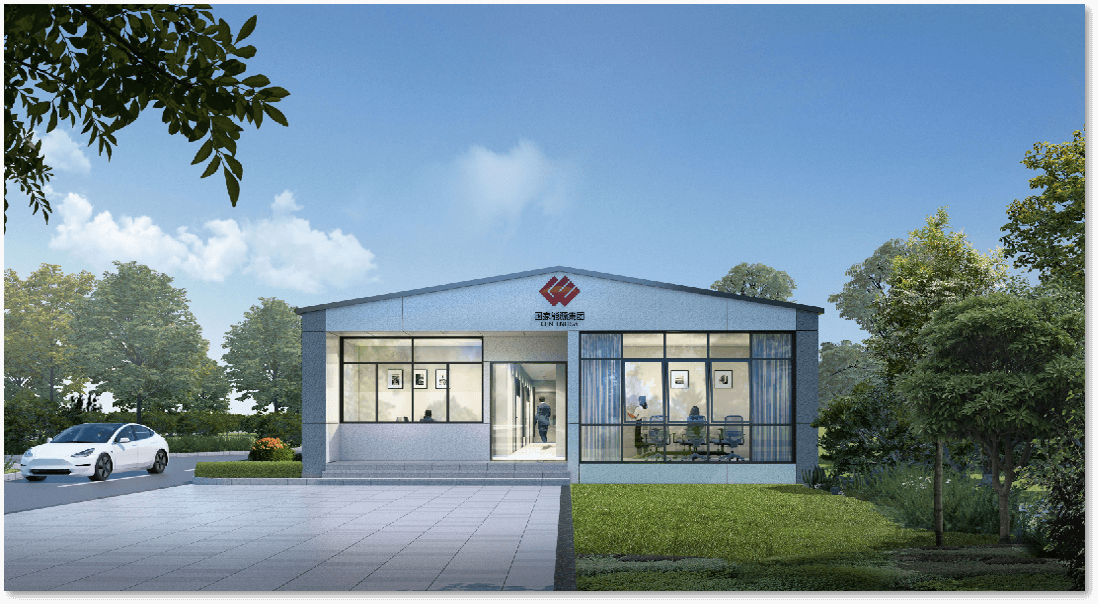

Module facilities

By integrating ‘box + facilities,’ we have developed unique functional modules that are fully factory-assembled and can operate independently or be combined as needed. Our product range is highly versatile, designed to fit a wide array of environments such as data centers, energy storage facilities, marine engineering projects, mobile security outposts, cultural and tourist destinations, among others, offering extensive applications across numerous industries.

Structural Type

-

Steel - Structured MiC

The structure is predominantly built using a steel frame system, resulting in a sturdy steel module unit composed of vertical steel columns, horizontal beams, and self-supporting flooring. This steel framework is designed to be lightweight, which simplifies the interconnection of module units. This design approach offers flexibility in architectural space planning and is well-suited for a diverse range of building applications, including commercial structures, residential complexes, educational facilities, and...

Process Flow of Steel-structured MIC

01. AI intelligent design

02. Component manufacturing

03. Structural final assembly

04. Decoration

05. Packaging and transportation

06. On-site hoisting

-

Concrete MiC

Buildings are formed by using concrete as the basic material to pre - fabricate and process modular units according to standard dimensions and specifications in a factory, and then transporting them to the site for assembly.

Process Flow of Concrete MiC

01. Mold Design

02. Mold Installation and Acceptance

03. Binding Reinforcement Cage

04. Embedded Concealed Items

05. Concealed Acceptance Before Pouring

06. Concrete Pouring

07. Formwork Removal

08. Dismantling the Formwork

09. Curing and Storage

Full Lifecycle Solutions for Modular Buildings

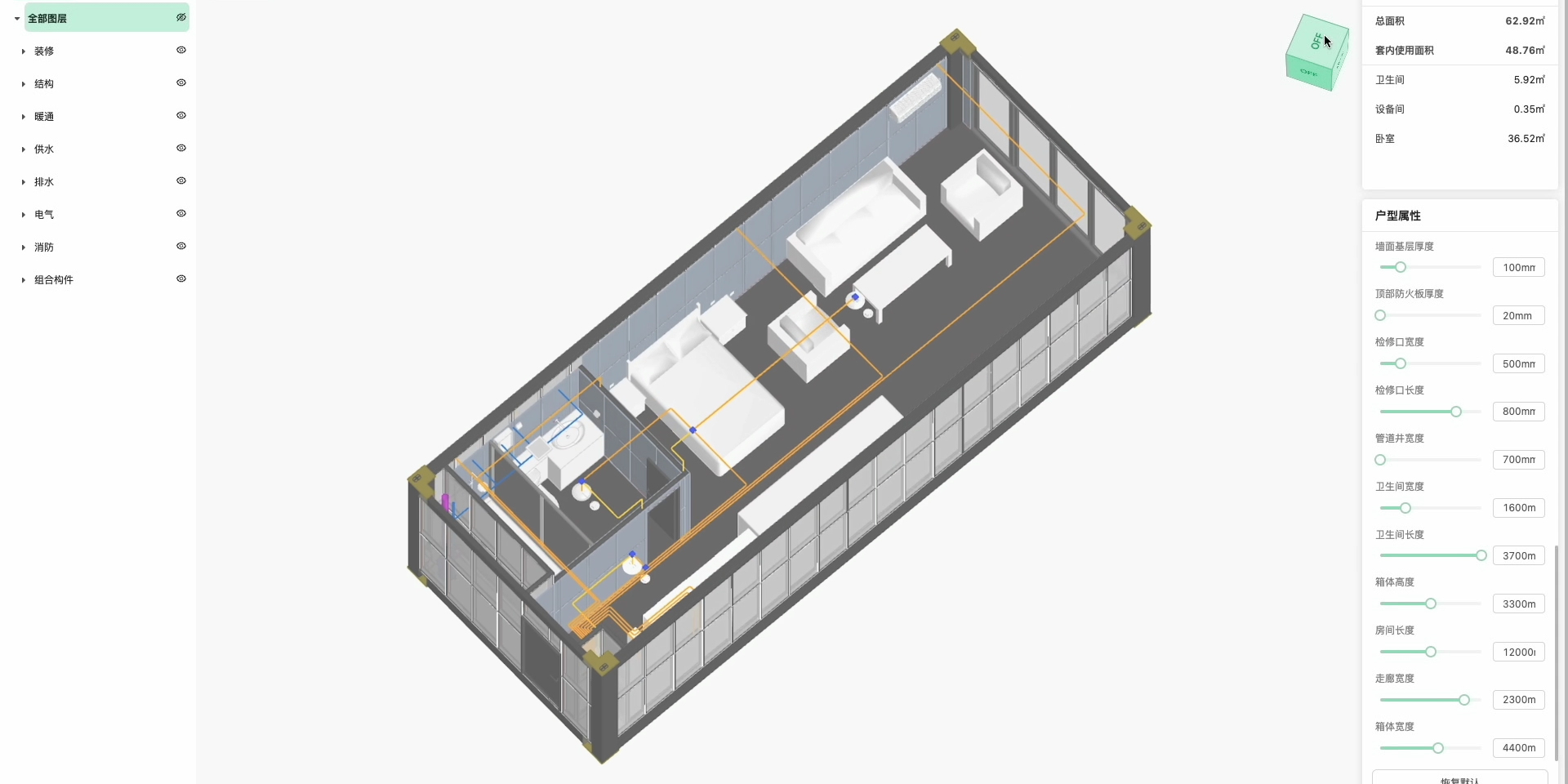

AI design

Transitioning from Manual to Intelligent Design

CSCEC Science and Industry Greentech Corporation Limited has launched a tailor-made AI Design Platform for modular construction. This platform leverages artificial intelligence to standardize and automate the design workflow. Equipped with predefined parameters and models, the AI rapidly generates design options that meet specific criteria, significantly boosting design efficiency.

Moreover, the AI Design Platform ensures consistency and quality in design outcomes, providing robust technical backing for modular construction projects. This approach simplifies the design stage and strengthens the overall project execution. It guarantees that each module is produced to exacting standards, reduces the likelihood of errors, and accelerates the construction schedule.

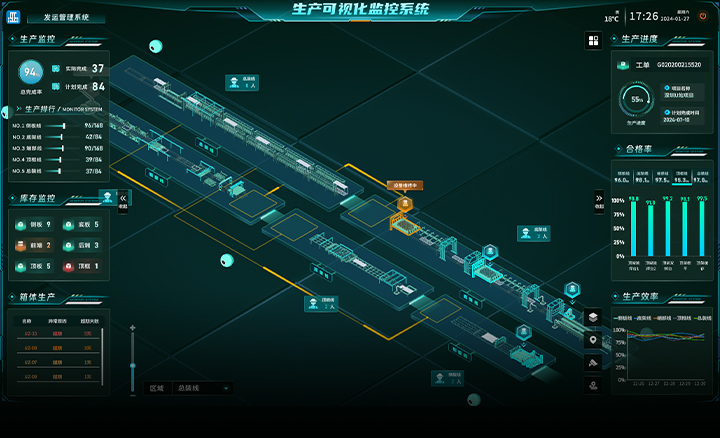

Intelligent Manufacturing

Industrialized manufacturing, precise and controllable.

We have achieved a digitized and visual approach to managing the entire construction process, from module fabrication to on-site assembly, by integrating intelligent construction technology with a full life cycle information management system. Utilizing high-precision 3D laser scanning, we ensure the exact measurement of assembled modules, which also eliminates the risks associated with high-altitude work and increases inspection efficiency by over 300%.

The use of smart construction machinery has significantly enhanced our delivery capabilities, leading to a factory-based intelligent construction process that harmoniously combines high efficiency with precise accuracy and consistent safety standards.

Intelligent Transportation

Finished product protection and transportation

Relying on the digital twin management platform, each module’s transport status can be grasped in real time, and real-time dispatching can be conducted for warehouses, transit warehouses, and construction sites.

Intelligent construction

Intelligent construction, precise and efficient.

Through the integration of a digital twin platform, we bridge the gap between on-site management and factory operations. This technology enables real-time monitoring and management of planned progress, equipment, and personnel, ensuring that key milestones are met with greater accuracy. By streamlining these processes, we not only improve the achievement rate of critical project nodes but also guarantee the smooth and efficient execution of the project from start to finish.

Information Integration

Information integration, sharing and collaboration.

By employing Building Information Modeling (BIM) and advanced information technology, we facilitate the seamless transmission and sharing of information and data throughout the entire life cycle of project construction. This approach ensures that all stakeholders have access to the latest project details, enabling efficient collaboration and decision process.

Application Scenarios

Green Technology Integration: A Synergistic Approach to Environmental Protection and Energy Efficiency, Pioneering a New Era of Sustainable Growth. Everything can be modularized.